A range of companies, large to small scale is involved in the plastic-based manufacturing industry.

In the case of plastic items produced through injection molding, the largest cost component is the cost of the molds. Especially, for small batch productions, the cost of mold design and manufacturing is exorbitant. Consequently, the local manufacturers try nonconventional methods on an attempt and error basis to develop low-cost molds for little batch productions. This paper presents some of the key issues faced by local, medium and small-scale manufacturers in designing and manufacturing plastic injection molds for medium to small batch production.

For Free, Demo classes Call: 8149467521

Registration Link: Click Here!

An injection molded product provides a lot of information about the design features of the associated mold. The mold designers use these evidences to decide some features of the mold while the rest of the design is performed based on the personal experience and approximations. This practice leads to numerous problems affecting the final product quality significantly. This also leads to poor utilization of materials, drop in overall effectiveness of the production process, and the increased cost of the mold itself.

In order to achieve dimensional stability, we should optimize the material we are going to select, optimize the part design and optimize the overall process.

What is molding

Molding is the manufacturing process used to create plastic components using a core and cavity.

Basic molding processes used for manufacturing?

- BLOW MOLDING

Air is blown into a plastic tube to take the shape of the mold.

- INJECTION MOLDING

It is a very complex dynamic process of injecting a hard-molten material into a colder mold that material is going to solidify, cool, shrink in order to develop stresses and mold is going to open up and then the parts are going to cool down to the final dimensions.

Applicable for polymeric material thermoplastic material and thermoset material as well

We can mass produce the very complex parts with dimensional stability

- REACTION INJECTION MOLDING

This process needs a curing reaction to occur within the mold. Rest of the process is similar to injection molding.

- SANDWICH

Two polymers or more are injected one after the other through the same gate in one or more cavities

- COMPRESSION

It is a way of molding during which the molding material generally preheated is first placed in an open heated mold cavity.

Materials for molding

ABS M30

ABS-M30 is best for conceptual modeling, Functional prototyping, manufacturing tools and production parts. This material has greater strength than standard ABS.

PC ABS

PC ABS may be a high impact engineering thermoplastic with heat resistance ideal for functional prototyping, tooling and low volume manufacturing.

For Free, Demo classes Call: 8149467521

Registration Link: Click Here!

Steps to be followed in the molding process

Injection>clamping>Dwelling>Cooling>Mold opening>Ejection

Mold Tools tab in SOLIDWORKS

SOLIDWORKS Mold Tools are available in SOLIDWORKS Standard, SOLIDWORKS Premium, and SOLIDWORKS Professional.

To enable the SOLIDWORKS Mold Tools interface, right click on the Features tab (or any Command Manager tab) within the command manager and choose “Mold Tools”. this might activate the Mold Tools tab.

The SOLIDWORKS Mold Tools interface are divided into four main areas (from left to right):

- Surface Preparation tools contains common surface tools

- Three Analysis tools

- Four Model preparation tools

- Mold Tools

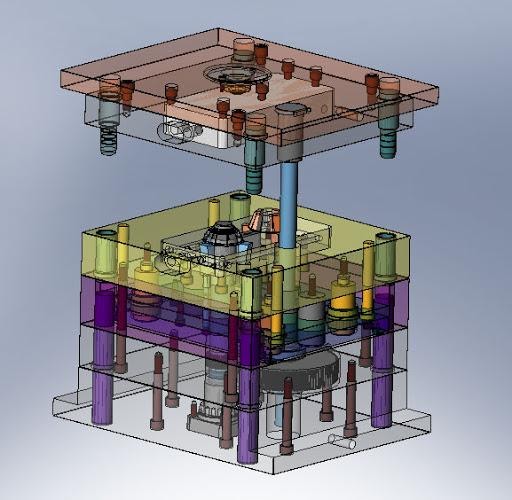

When you press the Insert Mold Folders button, three folders will automatically create under the Surface Bodies folder: Cavity Surface Bodies, Core Surface Bodies, and Parting Surface Bodies. subsequent steps will fill these folders, define where the Core or Cavity split are becoming to be.

Click on the Parting Lines button to define your Parting Lines. The dialogue box shows some colors. What do these colors mean? Green is for positive draft, means a Cavity or Core surface was created and yellow means there are “holes” through the part that require to essentially be plugged with Shut-off Surfaces. After the Parting Line is complete the Cavity and Core Surface Bodies will create in their respective folders.

Now we’re at the Parting Surfaces button. This creates the Surface which can split the tooling that we’ll create next. this might be done using the automated tools or manually if the parting line is just too complex.

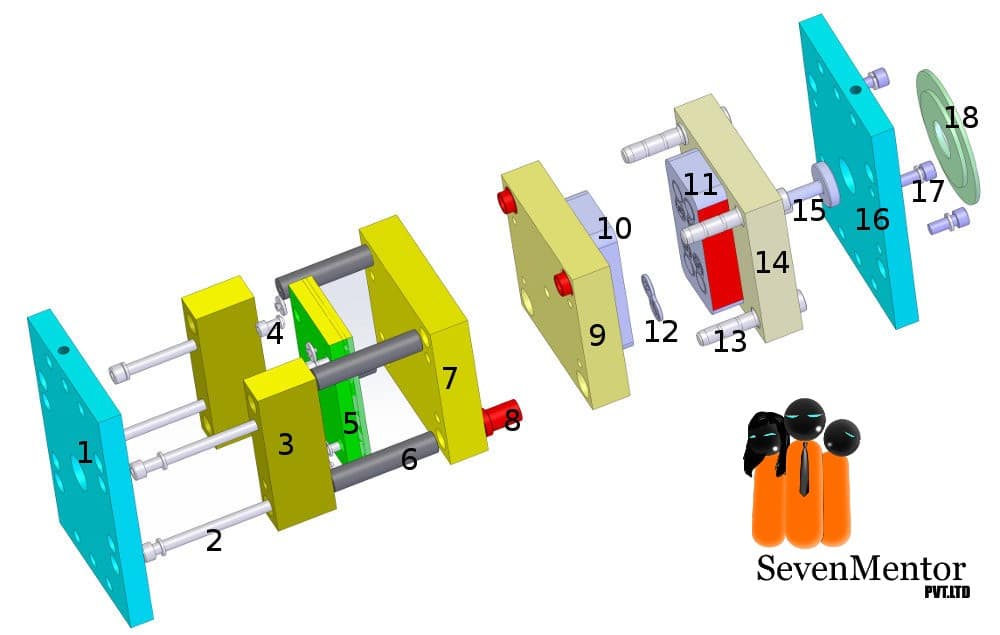

Finally, the Tooling Split command uses the surface bodies created within the folders above to separate the tool body, creating the solid Cavity and Core. If necessary, the Core command are often wont to create features like side cores, lifters, and core pins if action is required within the mold.

Mold Tools in SOLIDWORKS compared to Molding at Manufacturing Level

Tooling Split

If the tooling split fails and zip stands out as incorrect from the above errors, try manually knitting the acceptable surfaces together (using surfacing tools) to see whether the tooling split can succeed.

If the surfaces within the Cavity/core Surface Bodies folder cannot be manually knit with the Parting Surface Bodies, the Tooling Split command will fail. Use Surfacing Tools to correct the surfaces in order that they will knit.

Do we got to use each of those tools? No. they will be utilized in combination with manual methods also. Are Mold Tools always the simplest solutions? No, sometimes it’s faster or plain easier to make the Cavity and Core through alternate methods. However, once they are an honest fit your part, the SOLIDWORKS Mold Tools feature can

– less time in Cavity and Core creation

– Guide you through the steps you would like to form a successful Core/Cavity

– Make splitting surfaces easier to make

– Automatically organize surfaces within the appropriate surface folders

– Make side Core/Lifter/Ejector pin creation easier

For Free, Demo classes Call: 8149467521

Registration Link: Click Here!

Important factors to consider to meet your mold design goals for a successful production process.

DFM

Uniform wall thickness

Rib/Boss design

Material Selection

Mold Filling

Gate location

Gate Size

Unidirectional Filling Pattern

Melting Temperature

Filling Time

Packing Time

Cooling

Uniform mold surface temperature

Cooling line layout

Mold Steel Selection

Cycle Time

Warpage

Uniform shrinkage Rate

Author:

Shinde, Vaishnavi

Company: Seven Mentor Pvt. Ltd.

Call the Trainer and Book your free demo Class for now!!!